MPW/CyberShuttle Service

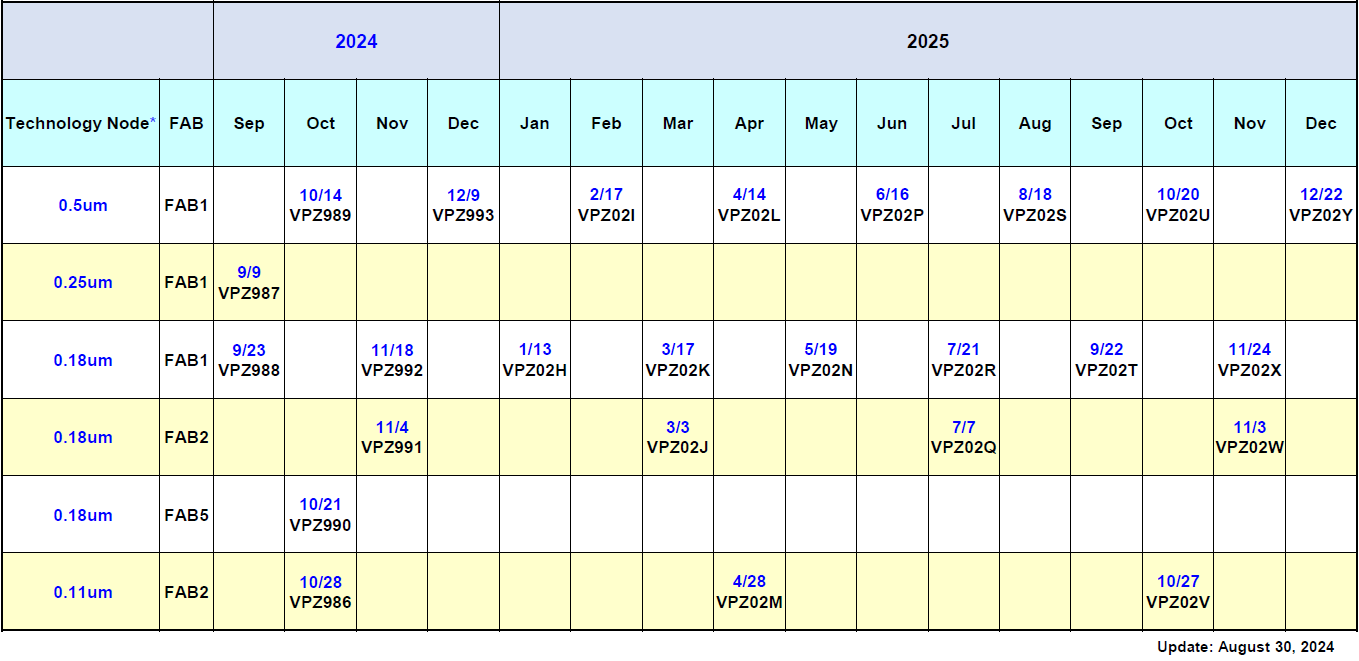

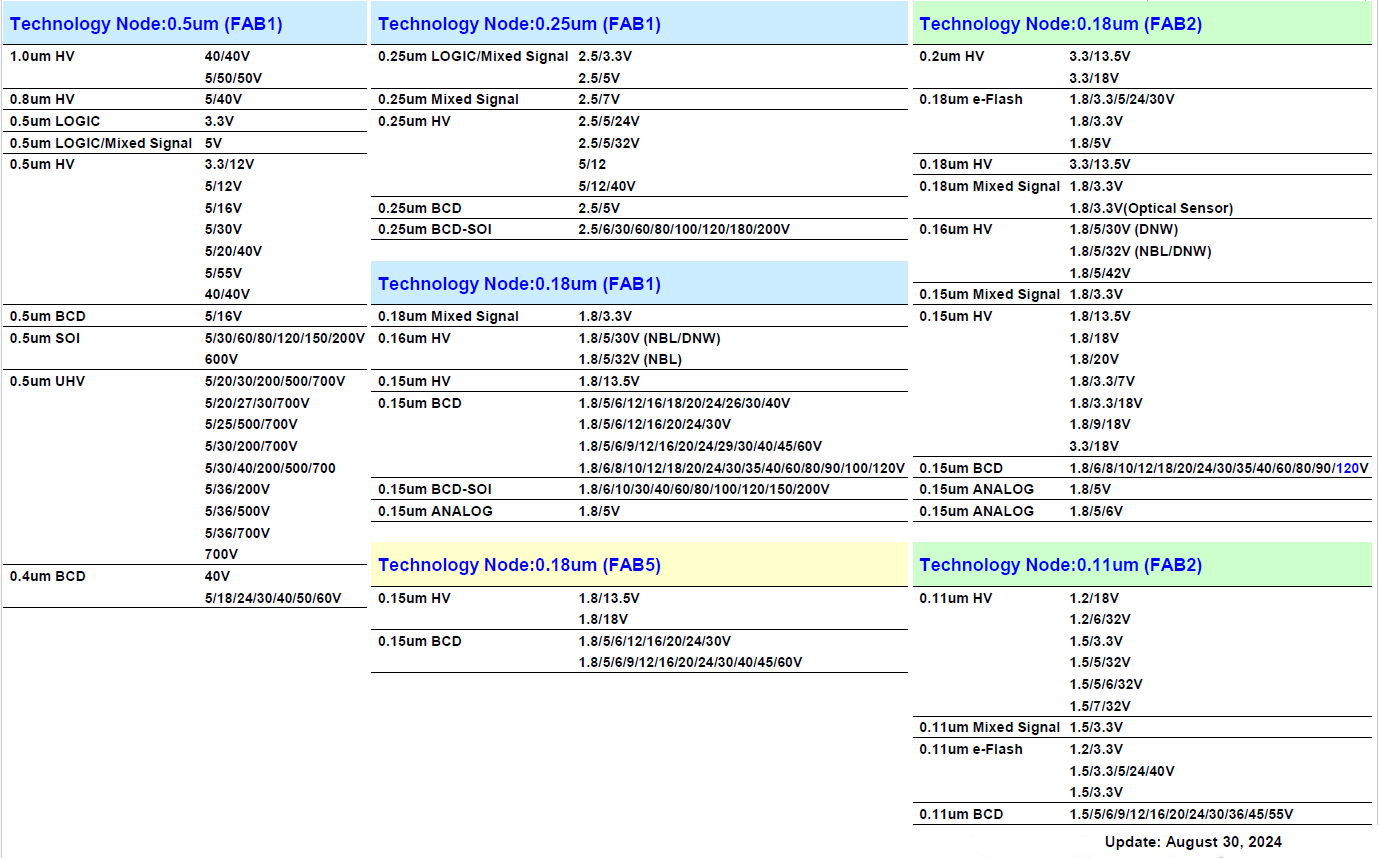

2025 TSMC CyberShuttle Service Plan

2025 TSMC CyberShuttle

Service Plan

Sharing increasing costs of mask tooling for multiple prototype and small production volume designs

As technology evolves, mask costs grow exponentially with each process generation. In the nanometer era, innovation and speed are the important keys of success factors. How to shorten the cycle of prototyping and new design/product development have been the major issues to conquer. If using the traditional ASIC flow for prototyping, it will cost too much money and time to verify. Once fail, the expense of photomask tooling and chip fabrication will be totally wasted.

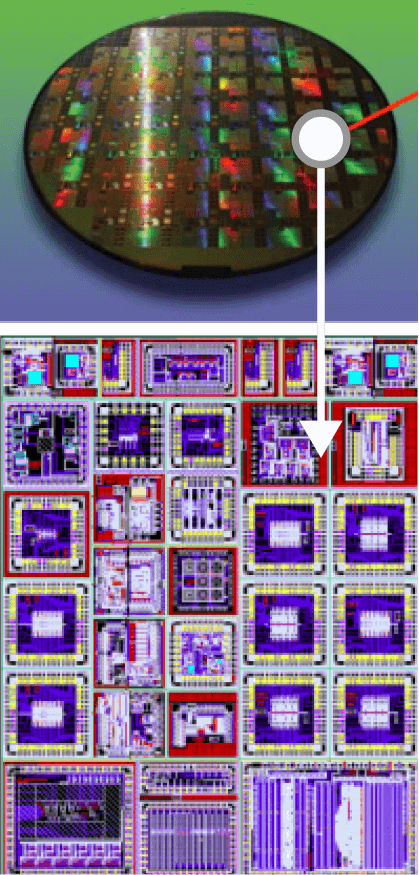

Fortunately, MPW (Multi-Project Wafer) service can provide a good solution to conquer the disadvantages of cost and time. MPW service allows customers to share the cost of a common mask set, which is processed through an engineering-run to speed new products and new designs to silicon-proven status. The benefits of MPW are bigger and bigger while the masking technology evolves.

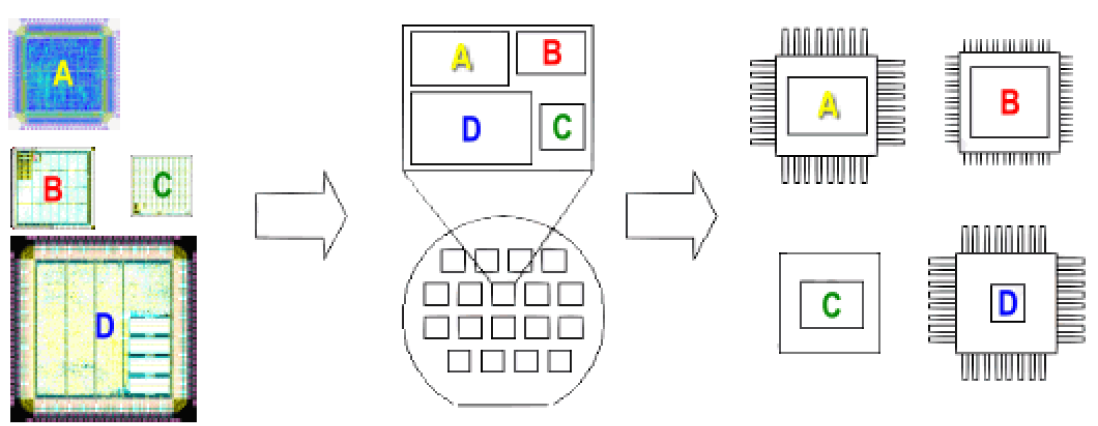

Different customers can deliver their design files to MPW service provider. Then their designs will be translated on to the same mask sets with proper allocation. After the process of chip fabrication, MPW service provider will deliver the chips to the relatively specific customer.

(See Fig-1)